Niax A-33/Jeffcat TD-33A/Lupragen N201

Niax A-33/Jeffcat TD-33A/Lupragen N201

Overview:

Chinese name: polyurethane catalyst A33

Alias: Catalyst A33, Polyurethane Catalyst A33, Catalyst A33, Foaming Catalyst A33, CAS 280-57-9, Dabco 33-LV, Niax A-33, Jeffcat TD-33A, Lupragen N201, Tegoamin 33 PC CAT TD33, Addocat 105, TEDA L33, foaming catalyst, polyurethane foaming catalyst, catalyst A-33, polyurethane catalyst A-33, liquid catalyst, liquid complex amine catalyst

Polyurethane Catalyst A33 is a gel catalyst mainly used as polyurethane foam.

Synonyms A33 Polyurethane Catalyst A33, Catalyst A33, Dabco 33-LV, Niax A-33, Jeffcat TD-33A, Lupragen N201, Tegoamin 33, PC CAT TD33, Addocat 105, TEDA L33, Foaming Catalyst A33

Content 33% Triethylene diamine solution

Form Solid

Application Flexible, semi-rigid, rigid urethane foam

Chemical composition:

33% solution of triethylenediamine.

Triethylenediamine is solid at room temperature and is not convenient for use as a polyurethane catalyst. In industrial applications, it is often melted in small molecule diols and configured to be used as an alcohol solution with a mass fraction of 33% (or other concentrations).

Commonly used diols are dipropylene glycol monoacetate, propylene glycol, diethylene glycol monoacetate (diethylene glycol), ethylene glycol and so on.

Product Physical Properties:

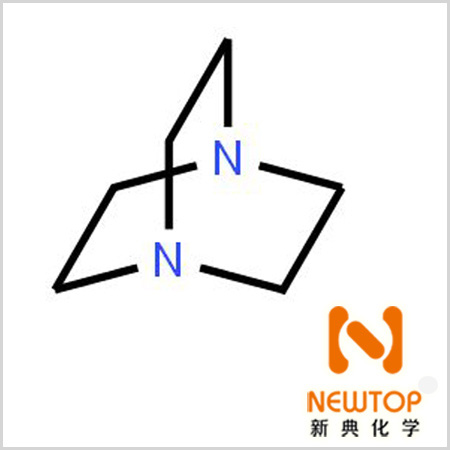

Molecular formula: C6H12N2;

Relative molecular mass: 112.17;

CAS No.: 280-57-9;

Purity ≥99%;

Moisture ≤0.5%;

Viscosity (25℃): 100mPa.s;

Density (20℃): 1.033g/cm3;

Flash point (PMCC): 79℃;

Vapor pressure (38℃): 266Pa

Product Usage:

The active ingredient of polyurethane catalyst A33 is triethylene diamine, the solution prepared by 33% of triethylene diamine and 67% of monoconjugated dipropylene glycol is mainly used as gel catalyst for polyurethane foam, which is widely used in flexible, semi-rigid, rigid polyurethane foam, coating, elastomer, In polyurethane foaming system, isocyanate firstly reacts with triethylene diamine to generate active complex. The nature of the complex is very unstable, once the urethane bond is generated, it will be free, which is conducive to further catalyzing, triethylenediamine has a strong catalytic effect on the gel reaction and foaming reaction, especially on the polyurethane and hydroxyl catalytic effect is more selective.A33 is mainly used as gel catalyst for polyurethane foams, and it is widely used in flexible, semi-rigid, rigid polyurethane foams, elastomers, coatings, etc.

Polyurethane Catalyst A33 Catalyst A33 Foaming Catalyst A33 CAS 280-57-9 Dabco 33-LV Niax A-33 Jeffcat TD-33A Lupragen N201 Tegoamin 33 PC CAT TD33 Addocat 105 TEDA L33 Foaming Catalyst 33-LV Polyurethane Foaming Catalyst 33-LV Catalyst A-33 Polyurethane Catalyst A-33 Liquid Catalysts

Storage and Transportation:

Should be kept sealed and stored in a dry, cool and ventilated warehouse

Packing:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

sales@newtopchem.com |

Telephone: |

86-152 2121 6908 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

Our Company

Since its establishment, the company has adhered to the service tenet of “integrity-based, customer first”, adhered to customer demand as the focus, market-oriented, adhered to technological innovation, management innovation and service innovation, and constantly implemented lean production, refined management, to provide customers with better products and services! The company has its own factory, research and development base, set up a strict scientific quality management system, and constantly committed to technological innovation, product innovation and management innovation, so as to ensure that our products have a certain competitiveness in the same industry. The factory is located in Jining City, Shandong Province, China, covering an area of 500 acres, and the current production capacity of various types of amines is 5,000 to 10,000 tons per year.

Our Advantages

Strict Quality Management

Our company strictly implements ISO9002 quality management standards and has established a complete quality management system to ensure the long-term stability of product quality.

Efficient Service

Our production is efficient and reliable, so we deliver on time and within delivery deadlines. At the same time, our team is always happy to help customers and strive to solve customer problems in a short time.

Competitive Price

We have long-term services in wholesale Polyurethane catalyst and have established long-term and stable cooperative relationships with many retailers and agents to provide our customers with reasonably priced products.

OEM Available

Our employee team has high R&D capabilities, superb design and development capabilities, skilled manufacturing technology, and rich product application experience, and can also meet OEM business needs.throughout the entire industry chain.