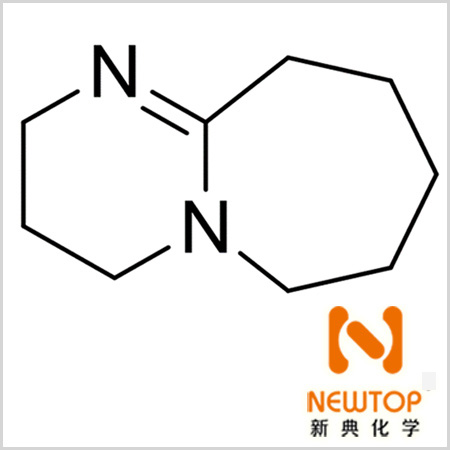

1,8-diazabicycloundec-7-ene/CAS 6674-22-2/DBU

1,8-diazabicycloundec-7-ene/CAS 6674-22-2/DBU

Overview:

1,8-Diazabicycloundec-7-ene is a colorless to light yellow transparent oily liquid with relatively low volatility, almost odorless, and alkaline. It changes color easily when exposed to light, and is hygroscopic and corrosive.

Name: 1,8-Diazabicyclo[5.4.0]undec-7-ene(DBU)

Product English Name: 1,8-Diazabicyclo[5.4.0]undec-7-ene

Packing Price: 200kg/drum

Purity specification: 98

Product Category: Pharmaceutical raw materials

6674-22-2 DBU Azabicyclic Diazabicyclo[5.4.0]undec-7-ene

Chinese name: 1,8-Diazabicycloundecene, Diazabicyclo, DBU

English name: 1,8-Diazabicyclo(5.4.0)undec-7-ene

Alias: 1,8-Diazabicyclo undec-7-ene, CAS 6674-22-2, catalyst DBU, epoxy accelerator DBU, polyurethane catalyst DBU, azabicyclo, diazabicyclo, Polycat DBU, Lupragen N700, PC CAT DBU

Molecular Formula: C9H16N2

Relative molecular mass: 152.2

CAS No.: 6674-22-2

Physicochemical properties:

1,8-Diazabicyclohexadec-7-ene is colorless to light yellow transparent oily liquid with relatively low volatility, almost odorless and alkaline. It is easy to change color when exposed to light, hygroscopic and corrosive.

Relative density: 1.04~1.07

Viscosity (25℃): 14mPa.s

Water solubility: soluble in water

Flash point(TCC):>96°C

Properties and Uses:

1,8-Diazabicyclohexadec-7-ene is used as a catalyst in the polyurethane industry, it is a very active low-odor gel catalyst, mainly used in applications requiring strong gel catalysis, including formulations containing alicyclic isocyanates or aliphatic isocyanates, which are less active than aromatic isocyanates and therefore require very strong catalysts.

1,8-Diazabicycloundec-7-ene catalyst activity is significantly enhanced with increasing temperature, for example, the catalytic rate constants of DBU for isocyanate-alcohol and isocyanate-water reactions at 70 °C are 67 and 35 times higher than those at 25 °C, respectively, whereas the catalytic activity of the commonly used bicyclic tertiary amine catalyst triethylenediamine is increased to 5 and 6 times its original catalytic activity, respectively;.

The 1,8-diazabicycloundec-7-ene catalyst can be used in formulations for integral skin foams, microcellular elastomers, and rigid foams.

The main use of DBU is as an excellent organic base deacidifier for drug synthesis. It can replace organic bases such as triethylamine, N,N-dimethylphenylamine, pyridine and quinoline, and is widely used in organic synthesis and semi-synthetic antibiotics, and obtains more satisfactory results in the dehalogenation reaction. It is widely used in the production of cephalosporin semi-synthetic antimicrobial drugs, such as ammonia and dichloroethane in the presence of DBU reaction to produce piperazine. It can also be used for epoxy resin hardener, rust inhibitor, can be formulated with high slow corrosion inhibitor, catalyst for other chemical reactions.

DBU in the application of epoxy resin DBU in the room temperature to 40 ℃ range of almost no curing reaction with the epoxy resin, and the temperature rises to 100 ℃ in 15min can make the epoxy resin gel. In epoxy resins, DBU is mainly used as a curing accelerator for epoxy resins used in the encapsulation of integrated circuits and electronic components. When used in the form of DBU salt, DBU is dissociated from it when it is heated during encapsulation to promote curing.

The combination of DBU and linear phenolic resin is a light yellow solid, which changes the disadvantage of DBU being easily hydrolyzed in humid environment. Therefore it consists of epoxy molding compound for IC encapsulation with good resistance to humidity and heat and high pressure steaming performance.

Storage and transportation:

It should be sealed and stored in dry, cool and ventilated warehouse

Packing:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the package cover as soon as possible after the original packaging to prevent moisture and other substances from mixing and affecting the performance of the product. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. Shower and change clothes after work. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

sales@newtopchem.com |

Telephone: |

86-152 2121 6908 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

Our Company

Since its establishment, the company has adhered to the service tenet of “integrity-based, customer first”, adhered to customer demand as the focus, market-oriented, adhered to technological innovation, management innovation and service innovation, and constantly implemented lean production, refined management, to provide customers with better products and services! The company has its own factory, research and development base, set up a strict scientific quality management system, and constantly committed to technological innovation, product innovation and management innovation, so as to ensure that our products have a certain competitiveness in the same industry. The factory is located in Jining City, Shandong Province, China, covering an area of 500 acres, and the current production capacity of various types of amines is 5,000 to 10,000 tons per year.

Our Advantages

Strict Quality Management

Our company strictly implements ISO9002 quality management standards and has established a complete quality management system to ensure the long-term stability of product quality.

Efficient Service

Our production is efficient and reliable, so we deliver on time and within delivery deadlines. At the same time, our team is always happy to help customers and strive to solve customer problems in a short time.

Competitive Price

We have long-term services in wholesale Polyurethane catalyst and have established long-term and stable cooperative relationships with many retailers and agents to provide our customers with reasonably priced products.

OEM Available

Our employee team has high R&D capabilities, superb design and development capabilities, skilled manufacturing technology, and rich product application experience, and can also meet OEM business needs.throughout the entire industry chain.