1,4-Butanediol BDO CAS110-63-4

1,4-Butanediol BDO CAS110-63-4

Overview:

Chinese name: 1,4-Butanediol (BDO)

Alias:Butylene glycol 4-butanediol 1,4-butanediol 4-Dihydroxybutane 1,4-dihydroxybutane

English Name:1,4-Butylene glycol~Tetramethylene glycol; tetramethylene glycol; 1,4-Butylene glycol; 75% 1,4-BUTANEDIOL; butane-1,4-diol; butane-1,1- diol

1,4-Butylene glycol (Butane-1,4-diol) is an organic substance with the molecular formula C4H10O2 and molecular weight 90.12. It is a colorless or light yellow oily liquid in appearance. Flammable, freezing point 20.1℃, refractive index 1.4461. soluble in methanol, ethanol, acetone, slightly soluble in ether. It is hygroscopic and has a bitter odor, but slightly sweet in the mouth.

Used as solvent and humidifier, also used in plasticizer, drug, polyester resin, polyurethane resin, etc.

Molecular formula(Formula): C₄HO₂

Molecular Weight(Molecular Weight): 90.12

CAS No.: 110-63-4

Product Name: Butanediol 4-butanediol 1,4-butanediol 4-Dihydroxybutane 1,4-dihydroxybutane

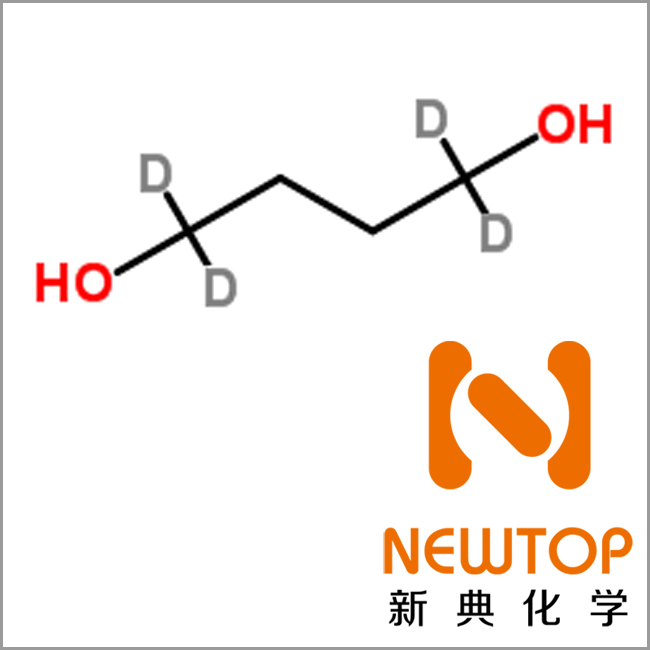

Molecular structure: See figure

Molecular formula: C₄HO₂

Molecular weight: 90.12

CAS No.: 110-63-4

EINECS No.: 203-786-5

MDL No. MFCD00002968

Physical and chemical properties:

Colorless, oily liquid, not easy to ignite. In contact with high heat, open flame or oxidizer, there is a risk of combustion.

Freezing point ≤19.0℃

Mass fraction of 1,4-butanediol≥99.5%

Bromine value ≤0.10%

Refractive index 1.445~1.446

Water content ≤0.10%

Hydroxyl value ≤0.2%

Chromaticity (platinum a cobalt color) ≤25

Preparation:

- Acetylene method: 1,4-butynediol is made by reacting acetylene and formaldehyde in the presence of Cu-Bi catalyst at 98kPa and 80-95℃. The latter is then catalyzed by nickel skeleton and hydrogenated at 1.372-2.06 MPa, 50-60°C to 1,4-butenedioate, followed by further catalytic hydrogenation with Ni-Cu-Mn/Al2O3 (13.7-20.6 MPa, 120-140°C) to 1,4-butanediol, which is then purified by distillation after removal of metal ions by ion exchange resin. 2. Maleic Anhydride Hydrogenation method 3. Butadiene method Acetyl oxidation reaction of 1,3-butadiene with acetic acid and oxygen to produce 1,4-diacetoxy-2-butene, then hydrogenated and hydrolyzed to make 4. 1,4-dichlorobutene method 1,4-dichlorobutene is an intermediate product of the process of producing chlorobutadiene from butadiene, which is used as raw material, hydrolyzed and hydrogenated to obtain 1,4-butanediol.

Uses:

1,4-butanediol is an important organic chemical and fine chemical raw material, and is the basic raw material for the production of polybutylene terephthalate (PBT) engineering plastics and PBT fiber; PBT plastic is one of the five most promising engineering plastics.

1,4 butanediol is the main raw material for the production of tetrahydrofuran, which is an important organic solvent. The polytetramethylene glycol ether (PTMEG) obtained after polymerization is the basic raw material for the production of high-elasticity spandex (Lycra fiber). Spandex is mainly used in the production of high-elasticity knitted products such as advanced sportswear and swimwear.

γ-butyrolactone, a downstream product of 1,4-butanediol, is the raw material for the production of 2-pyrrolidone and N-methylpyrrolidone products, from which a series of high value-added products such as vinylpyrrolidone and polyvinylpyrrolidone are derived, which are widely used in pesticides, pharmaceuticals and cosmetics.

Applications:

Used as solvent and humidifier, also used to make plasticizer, drugs, polyester resin, polyurethane resin, etc.

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse

Package:

200KG/drum Storage: It is recommended to store in dry and cool area with proper ventilation. Please fasten the lid as soon as possible after the original packaging to prevent the mixing of other substances such as water and other substances from affecting the product performance. Do not inhale dust and avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and wash them before use. Maintain good hygiene habits.

Our Company

Since its establishment, the company has adhered to the service tenet of “integrity-based, customer first”, adhered to customer demand as the focus, market-oriented, adhered to technological innovation, management innovation and service innovation, and constantly implemented lean production, refined management, to provide customers with better products and services! The company has its own factory, research and development base, set up a strict scientific quality management system, and constantly committed to technological innovation, product innovation and management innovation, so as to ensure that our products have a certain competitiveness in the same industry. The factory is located in Jining City, Shandong Province, China, covering an area of 500 acres, and the current production capacity of various types of amines is 5,000 to 10,000 tons per year.

Our Advantages

Strict Quality Management

Our company strictly implements ISO9002 quality management standards and has established a complete quality management system to ensure the long-term stability of product quality.

Efficient Service

Our production is efficient and reliable, so we deliver on time and within delivery deadlines. At the same time, our team is always happy to help customers and strive to solve customer problems in a short time.

Competitive Price

We have long-term services in wholesale Polyurethane catalyst and have established long-term and stable cooperative relationships with many retailers and agents to provide our customers with reasonably priced products.

OEM Available

Our employee team has high R&D capabilities, superb design and development capabilities, skilled manufacturing technology, and rich product application experience, and can also meet OEM business needs.throughout the entire industry chain.